In the heart of Jiangxi Province, a technological marvel is unfolding in the fields of Wanzhou County. At Mama Jia Ecological Agriculture Development Co., Ltd., Chang Chuiming and his team are spearheading a farming revolution. Instead of using traditional methods of sowing rice, they have embraced an innovative technique: 3D-printed rice seeding. This cutting-edge approach is transforming rice cultivation by offering concrete, data-driven improvements in efficiency, cost, and yield.

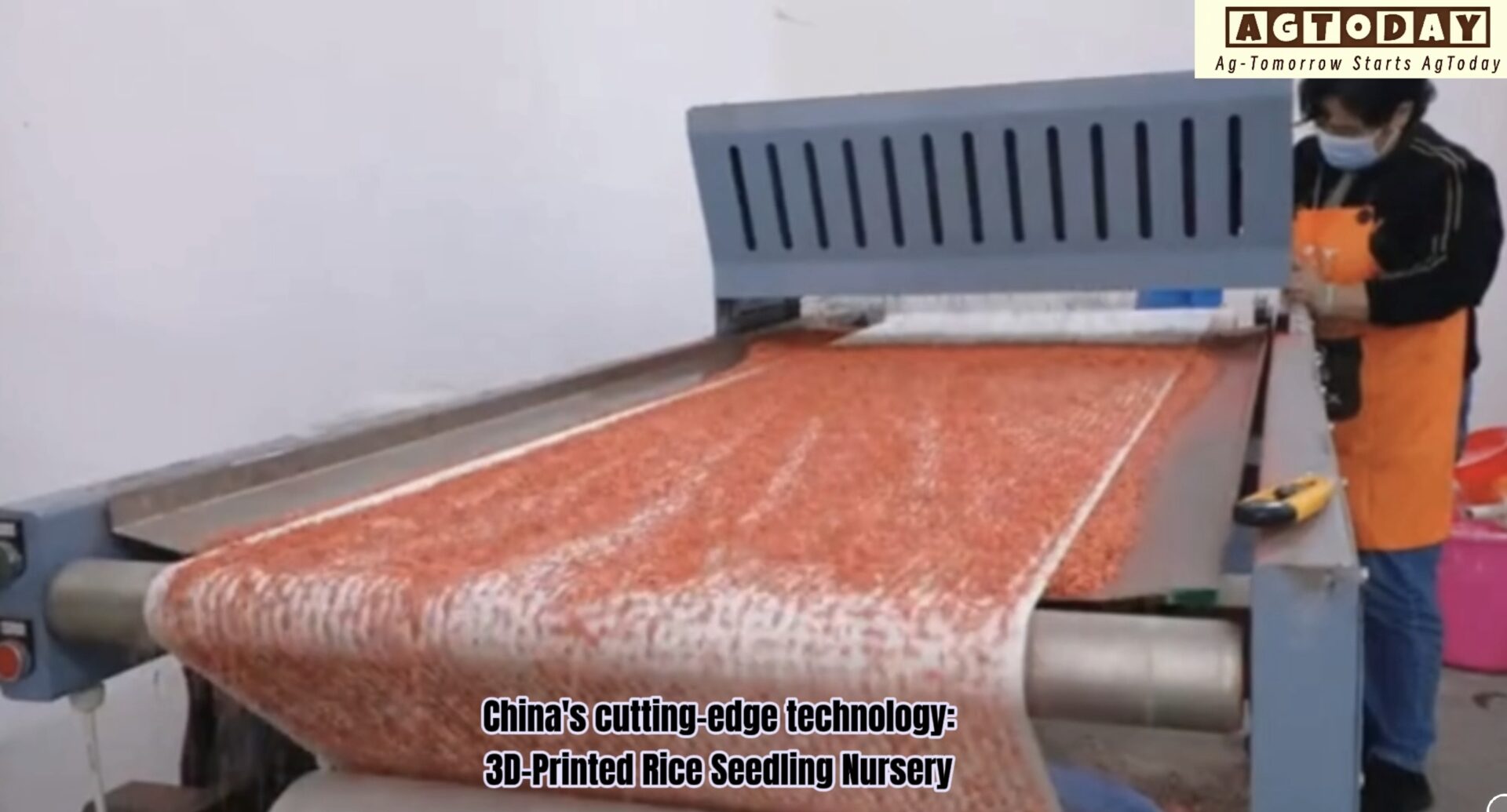

The process of 3D printing rice seeds is similar to paper printing. Rice seeds are carefully deposited into a precision seed-positioning machine while nursery paper travels along a conveyor belt. The seeds fall onto the paper and adhere to pre-set adhesive dots. Any excess grains are then vibrated off. The result is a neatly “printed” sheet of seeds, with each dot holding one to two grains and perfectly aligned with the holes of nursery trays. This precision ensures uniform spacing, which is a sharp contrast to traditional sowing methods that often result in random seed distribution, uneven growth, and wasted resources.

At first, some local farmers were skeptical. “Why not just scatter the seeds?” they remarked. This seems unnecessary!” they remarked. However, the benefits of this technology soon became apparent. Reflecting on his experience with traditional methods, Chang Chuiming explains: “Sparse seedlings forced us to use 60–70 trays and 2–2.5 kg of seeds per acre. Overcrowding stunted germination, leading to inconsistent growth and higher costs.”

By comparison, 3D-printed nursery paper has revolutionized these metrics. Each sheet contains 42 glue dots per row made from biodegradable ingredients like starch and kudzu root powder. The adhesive ensures precise seed placement, addressing uniformity issues while remaining environmentally friendly.

Key Statistical Advantages of 3D-Printed Seeds

- Seed efficiency: Traditional methods required 2-2.5 kg of seeds per acre. With 3D printing, this amount is reduced to 1.5 kg—a 40%-50% reduction in seed usage. This translates to direct cost savings of 50-60 yuan ($7-$8.50 USD) per acre.

- Yield and Growth Performance: Trials conducted by the Jiangxi Academy of Agricultural Sciences demonstrated significant improvements:

- Seedlings rooted five days faster post-transplant compared to traditional methods.

- There were no instances of “yellowing” or “leggy growth,” which are common issues that reduce survival rates by up to 20% in conventional sowing.

- Overall rice yields increased by 8-10% in 3D-printed fields.

- Resource Optimization: The precision of 3D seeding reduced tray usage by 30-40%. Instead of using 60–70 trays per acre, farmers now only need 40–50, which reduces labor and material costs.

- Storage and Flexibility: The printed nursery paper can be rolled up and stored for up to six months, enabling farmers to plan their sowing schedules more flexibly. This is particularly crucial during the “double rush” period, when farmers must simultaneously harvest early rice and plant late rice.

The “Rush Harvesting and Rush Planting” deadline and time savings

During this intense phase, delays can be catastrophic. In traditional farming, seedlings often outgrow trays within 20–25 days, becoming weak “tall-leg seedlings” with survival rates as low as 60–70%. However, 3D-printed seeds resist overcrowding and can be stored for an additional 20–30 days, ensuring healthier transplants and boosting survival rates to over 90%. “It adds one step but saves countless headaches later,” Chang Chuiming emphasizes. The time buffer also allows farmers to optimize planting schedules and potentially avoid adverse weather or labor shortages.

Environmental Impact: Beyond economics, the technology aligns with the goal of sustainable agriculture. By reducing seed waste and using biodegradable paper made from 100% natural starch and kudzu root, farmers can reduce their carbon footprint. A study by the academy estimates that adopting 3D-printed sowing could save 15-20 tons of seeds annually across Jiangxi Province, which is equivalent to reducing CO2 emissions by 50-70 tons.

As Jiangxi farmers witness the technology’s tangible benefits, including higher yields, lower input costs, and ecological advantages, 3D-printed sowing is rapidly gaining traction. Chang Chuiming’s vision extends beyond local adoption. “This isn’t just innovation—it’s necessity. We aim to scale this technology to cover 50,000 acres within three years, empowering farmers across China.”

In conclusion, China’s high-tech agriculture is paving the way for a more efficient and sustainable future. The 3D printing of rice seeds, backed by robust data and real-world success, showcases how technology can revolutionize traditional farming. From cost savings of $7-$8.50 per acre to yield increases of 8-10%, and from labor efficiency to environmental stewardship, this innovation promises to benefit not only China’s rice production but also global food security. As this technology evolves and spreads, it could be a game-changer for agriculture worldwide.